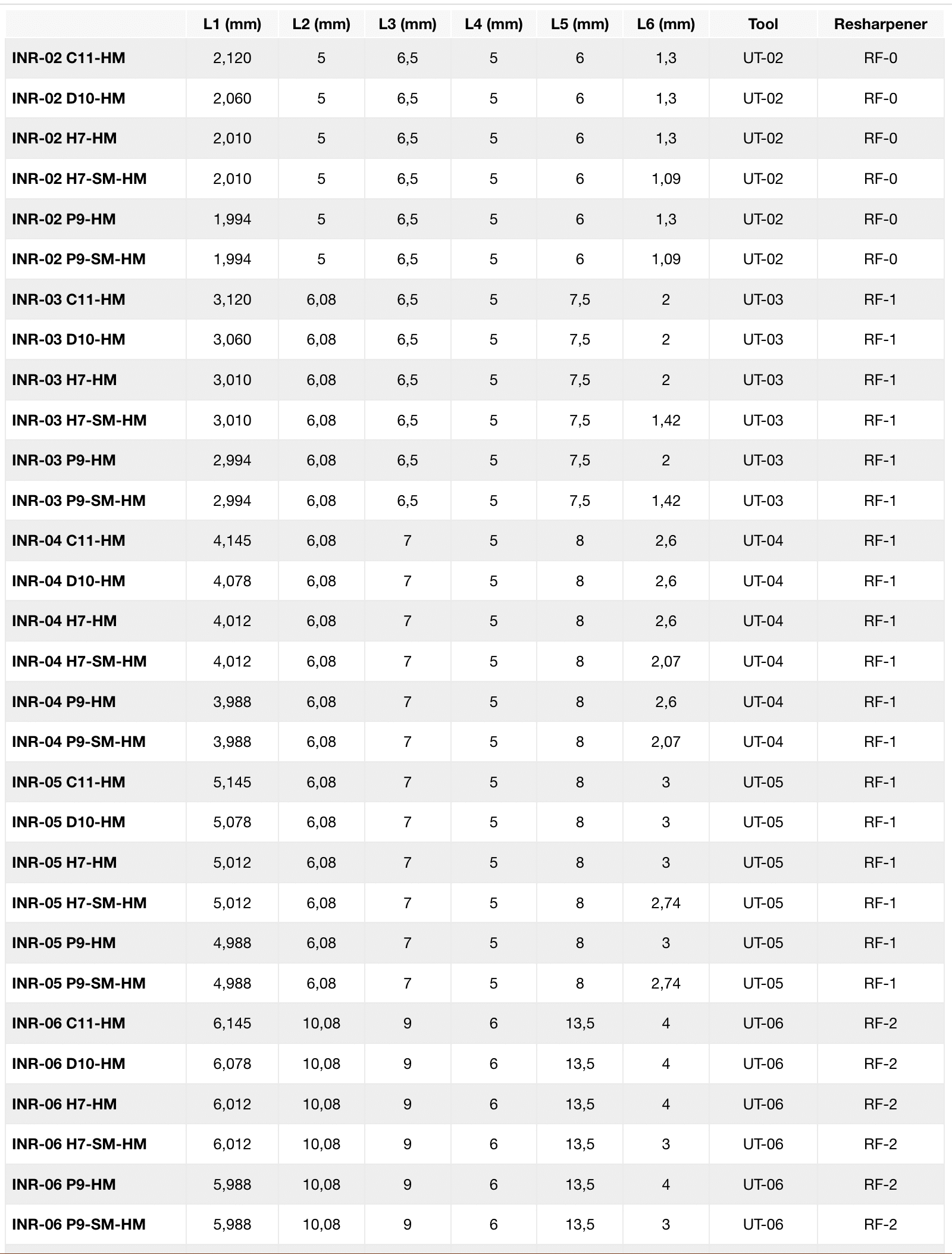

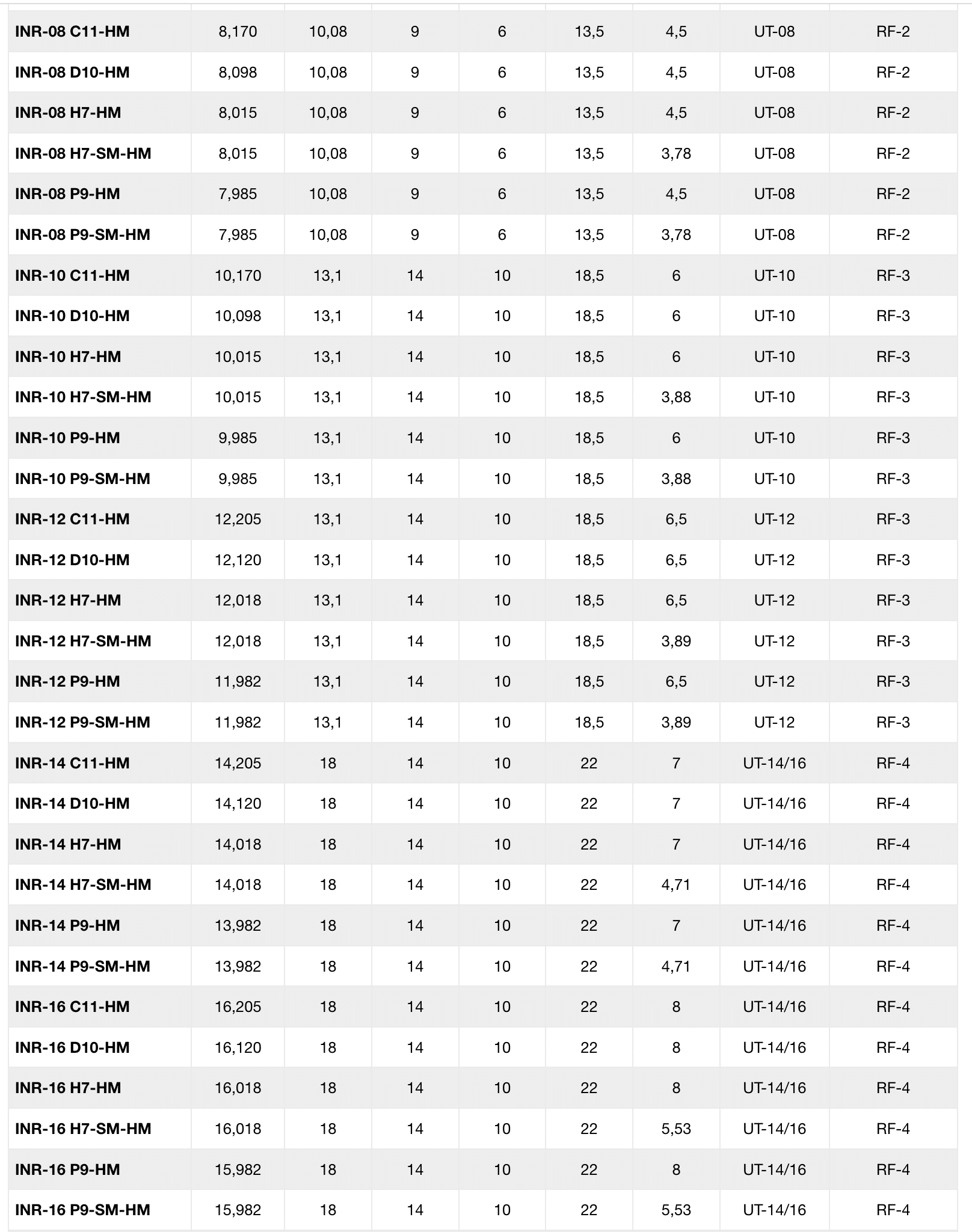

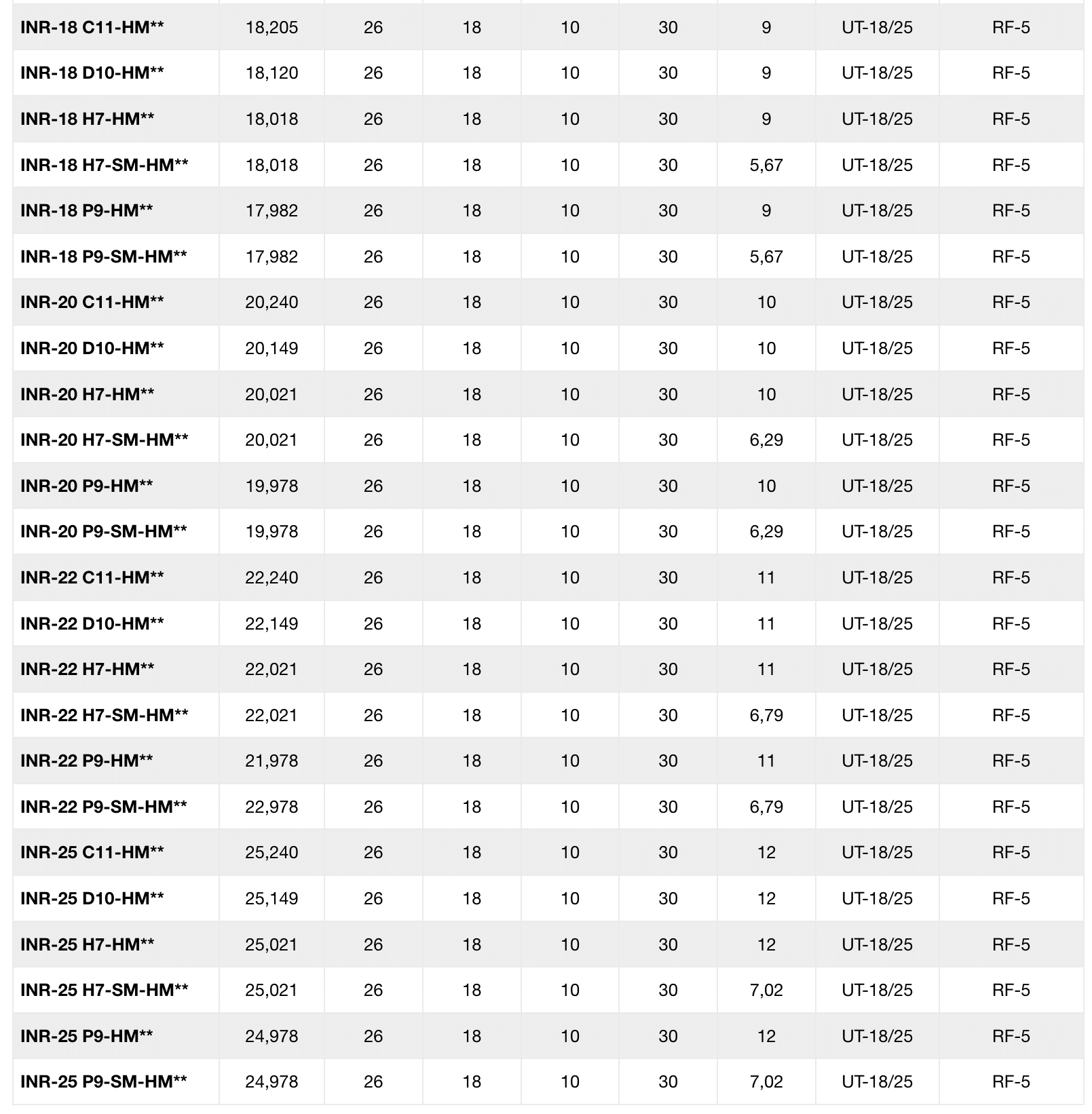

CARBIDE INSERTS (MM) REV

The broaching and slotting inserts are made of sintered alloy steel with a 13% cobalt content.

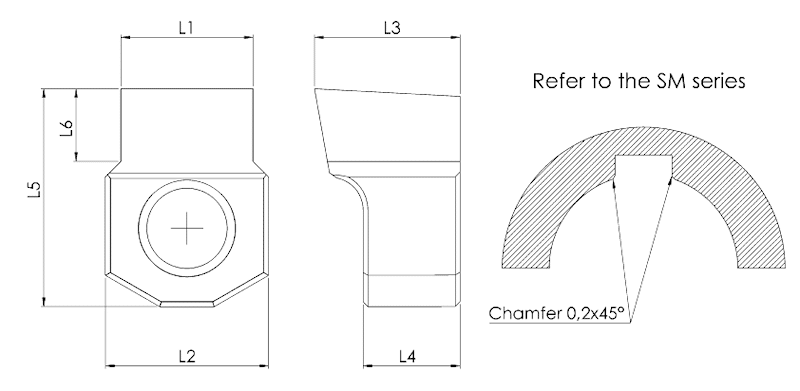

After the heat treatment, this material reaches a hardness of 72 HRC while retaining at the same time a high toughness and, consequently, a considerable impact resistance. After sharpening on all sides, the insert is TIN coated for increased wear resistance. The protruding shape of the inserts allows a high number of regrindings. The inserts whose reference ends with the suffix “SM” perform a 0.2×45° chamfer at the intersection point between the hole and the walls of the broached slot thus leaving the hole free of burrs. This type of chamfer can only be performed on UNI keyways.

We also produce special inserts upon customer request.

** For these insert sizes it is recommended to divide the machining into two phases: roughing and finishing.