BT/BTA Keyways broaching system on CNC machines

BT-BTA broaching systems are designed for making keyway seats and internal/external profiles of significant dimensions on CNC machines.

The BT/BTA broaching systems have been developed to machine internal keyways inside blind or through holes using CNC machine tools.

By using BT/BTA broaching systems it is not necessary to change machine tool to complete the production process. After the turning, the milling, the drilling, etc. it is possible to proceed with the broaching operation of the internal keyway without taking the work-piece off the machine tool, which means a great saving in time and money, and the result of the machining will be much more precise.

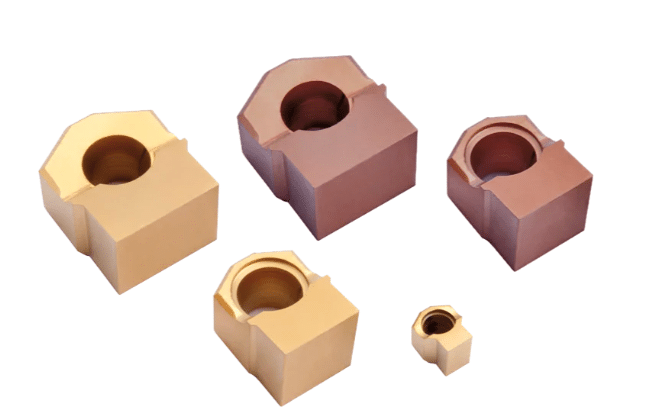

We propose two different solution for the internal keyway machining.

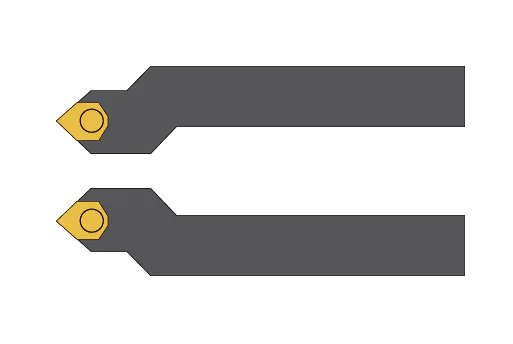

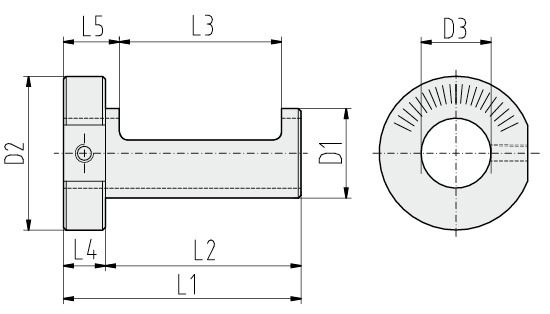

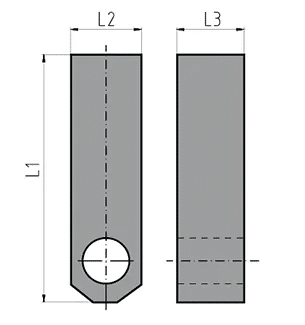

The first is the BT system, made of the insert holder and the insert, which is used on CNC machines (lathe, milling machines, machining centre) with a Y axis or on slotting machines. The perfect alignment between the tools and the work-piece is granted by the specific funcion of the CNC machine. The insert holder is available with cylindrical connection to the machine, two different measures in particular: Ø25 and Ø 32. The maximum broaching depth goes from 30 mm to 200 mm.

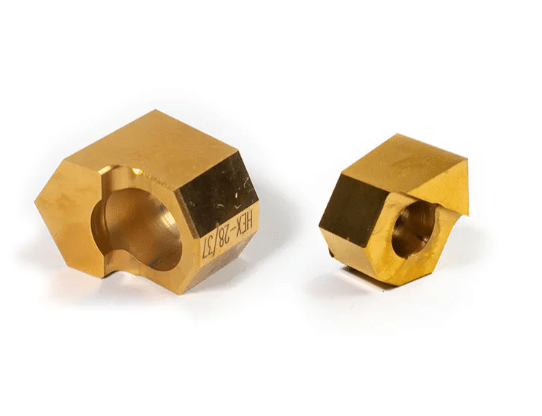

The second is the BTA system, made of the BT system (insert holder + insert) and the eccentric graduated bush. This “three tools broaching system” is useful when a machine tool without a Y axis is to be used. In this case, it is the eccentric graduated bush the one which guarantees the perfect alignment between the broaching tools and the work-piece. The alignment mistakes can be corrected by turning, clockwise or counterclockwise, the eccentric bush following the notches engraved on its collar. The eccentric graduated bush is available in three different measures of the outside diameter: 32 – 40 – 50 and the inside hole axis is shifted 0,5 mm from the bush axis.

The BTA broaching systems, which are patented, are a great novelty in the field of the internal keyway machining on CNC.

At the time being, in fact, all internal keyways broaching systems on CNC machine tools available on the market use “steady tools”, which means that the tools are not adjustable. As a consequence, the correction of the alignment of the tools needs several attempts and it is not driven by a graduated scale which, in the case of BT/BTA, made this operation faster and easier.