Motorized slotting head

The MOTORIZED SLOTTING head is the new slotting system for CNC lathes with motorized tool holders. The experience gained during these years in slotting machining gave BRIGHETTI MECCANICA the capacity to understand the biggest set of problems operators meet during a slotting machining and to develop correct solutions to apply to the equipment.

This tool was designed to obtain the maximum possible rigidity, thus allowing an optimum finish level of the machined surface. Furthermore, besides the operation being swiftly carried out, it affords a considerable advantage in that this type of processing gets implemented without the setting of the piece having to be repeated or done on another machine.

The main features of this new patented instrument are:

– A whole operativeness

The same slotting head can be used for both internal and external machinings. It’s necessary to chance the rotation of the motorized axis and turn the head of 180°.

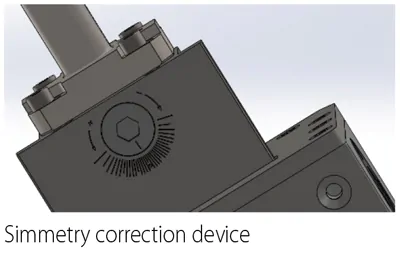

– Symmetry correction

The device placed in the front of the instrument has the purpose to correct simmetry mistakes. As this device leads to a movement of the insert holder along the machine Y axis, thanks to a rail, it is easy to use the motorized slotting head even on lathes with no Y axis. The capacity of the correction device goes from 0,5 mm Y+ to 0,5 mm Y-.

– Longitudinal correction

The MBT motorized heads are equipped with a longitudinal correction system which is necessary to guarantee the perfect linearity of the machining. To eliminate possible errors along Z axis, it is necessary to just turn clockwise or counterclockwise the screw placed in the rear part of the instrument.

– VERSIONS

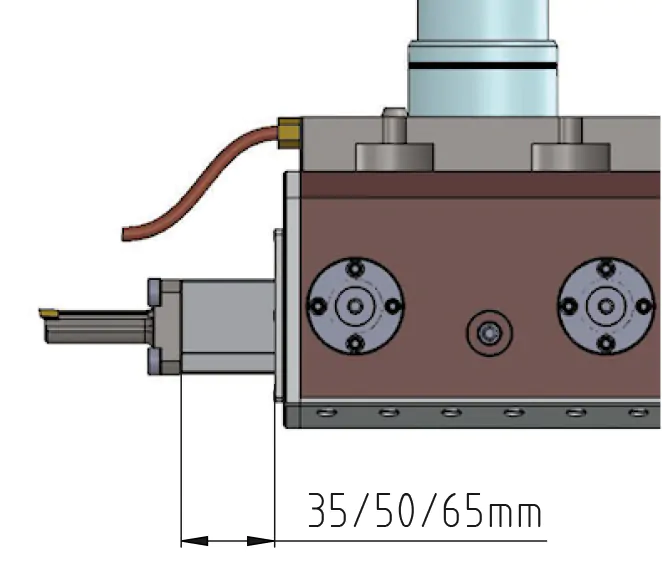

The motorized slotting head is produced with 3 different slotting depth:

- depth of 35mm: item ST-35

- depth of 50mm: item ST-50

- depth of 65mm: item ST-65

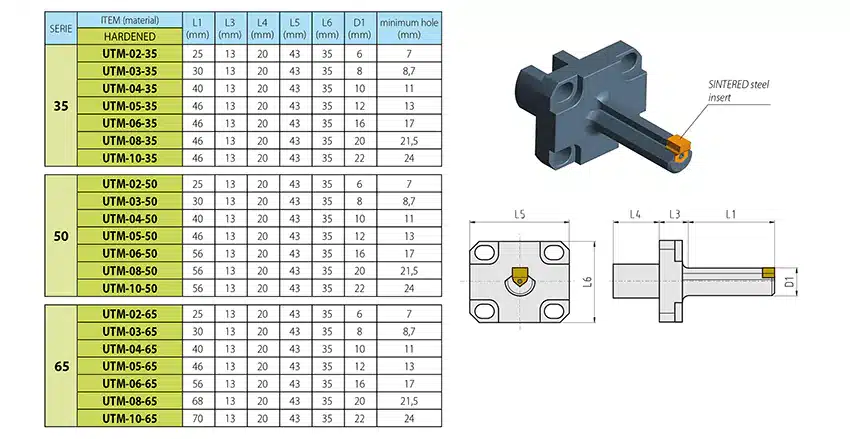

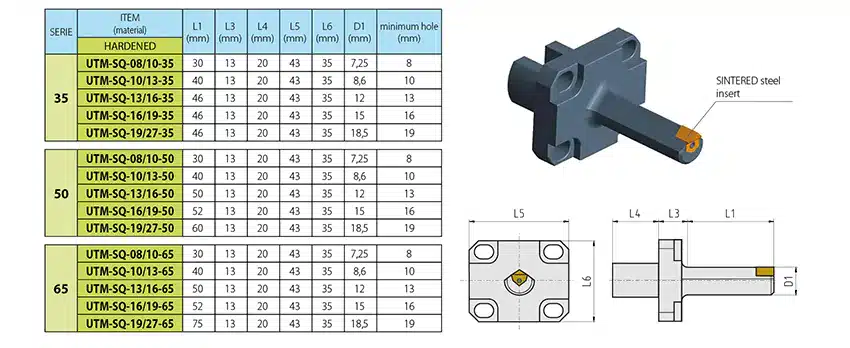

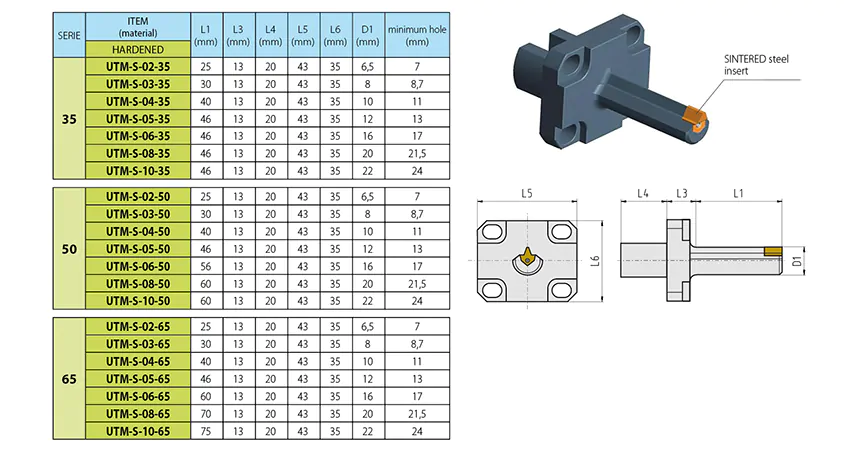

UTM-S series insert holder for machining special profiles (slots, gearings, evolving gearings, …)

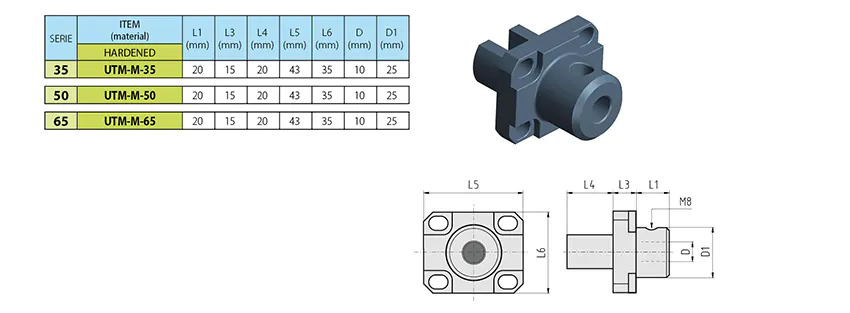

UTM-M series insert holder for integral inserts

MACHINE PROGRAMMING

As the experience with programs for standard slotting machining has been a good one, to help using this new instrument, our technicians develped new programs to quickly and easily set up the motorized slotting head. These new programs are suitable for the most popular CNC sfotware now on the market.

CUTTING PARAMETERS

To guarantee a lengthy duration of the insert and an optimal machining finish, it is advisable to keep to the suggested parameters (refer to the parameters table).

Maximum thickness obtainable on various materials and cutting parameters: